Aluminum Flood Plank System

The Hammerhead™ aluminum panel flood barrier system is a durable stop log flood barrier that enables you to protect doorways and other openings against flooding.

U-Channel Posts are installed on either side of the opening to be protected. These unobtrusive posts remain in place permanently and when flooding is expected are designed to receive a series of aluminum planks, which are stacked as needed to the height required.

The Hammerhead™ stackable “stop log” flood barrier is able to withstand water up to 6 feet and will protect your building, residence, or facility against all types of flooding.

This flood gate system is also ideal for areas where high wind or debris is expected as the fixed posts and clamped planks are durable, rigid and designed to handle heavy stresses.

Garrison’s Hammerhead System is Proudly Made in the USA

Meets requirements in NFIP Technical Bulletin 3

Flood wall height customized to your needs

Up to 12ft Wide Planks w/Center Posts for unlimited lengths

Protect Entrances and Doorways From Flooding

When you need durable flood protection, Garrison’s Hammerhead™ aluminum flood plank barrier is the right flood gate choice for your residential or commercial property.

Doorways and Window Wells

Loading Docks

Basement Stairwells

Perimeter Opening Protection

Garages and Ramps

Flood gates for passageways

Why Protect Against Flooding With Hammerhead™ Flood Panels?

Compactly stores and takes up minimal space. Simply stack flood barrier planks when not in use.

Easily deployed in advance of a flood by unskilled labor. Simply slide flood planks into posts and tighten down.

Durable enough to handle high winds and debris.

Serious flood protection against severe floods up to 6ft.

Customizable flood barrier heights and lengths, depending on your specific flood gate needs.

Reusable and long lasting stop logs with durable aluminum construction.

See Our Video About The

Hammerhead™ Aluminum Flood Plank Barrier

How Does the Hammerhead™ Flood Panel System Work?

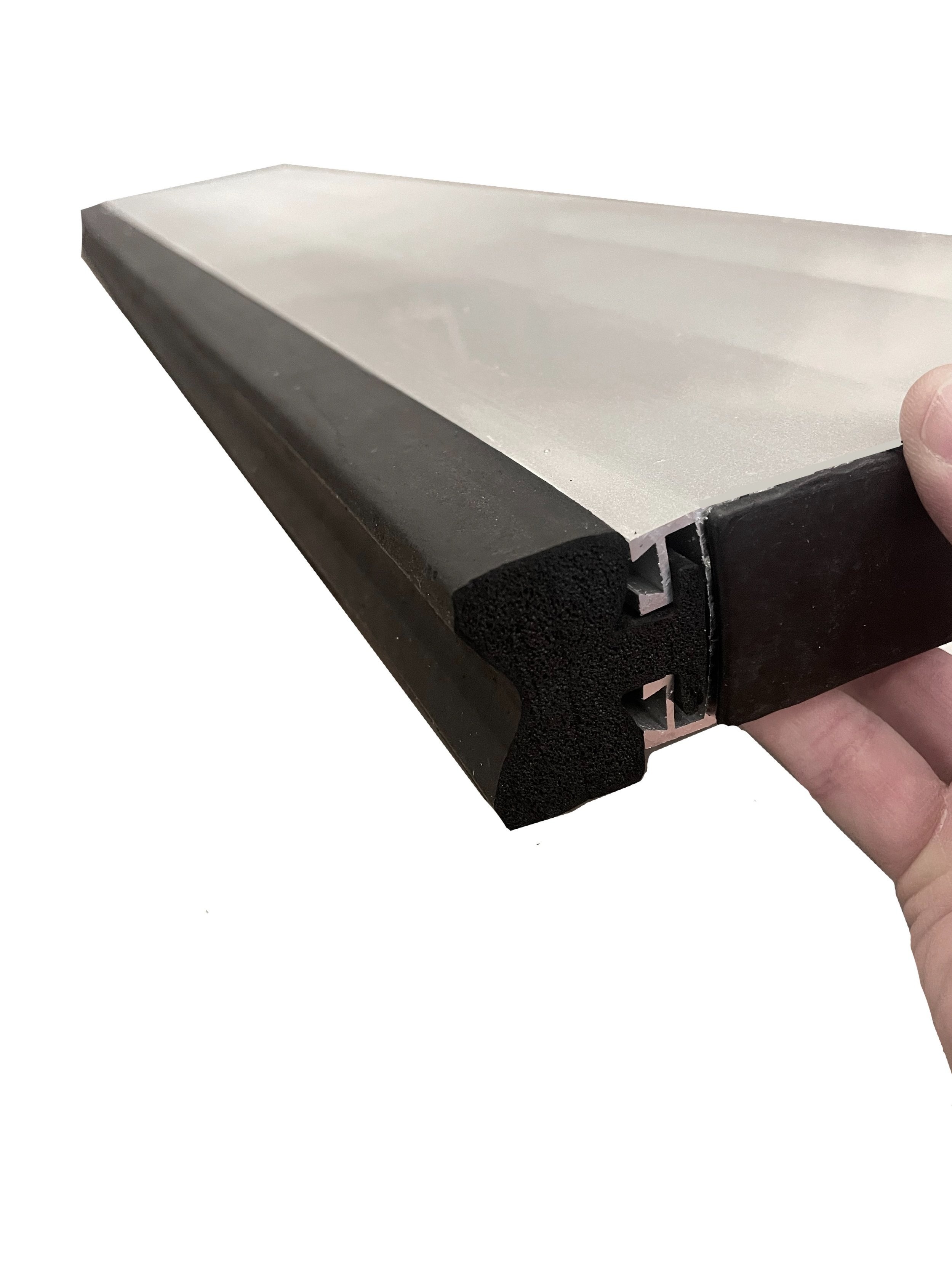

Hammerhead™ aluminum flood barriers utilize a series of aluminum planks (“logs”) that are slotted into support posts mounted on either side of the opening to be protected.

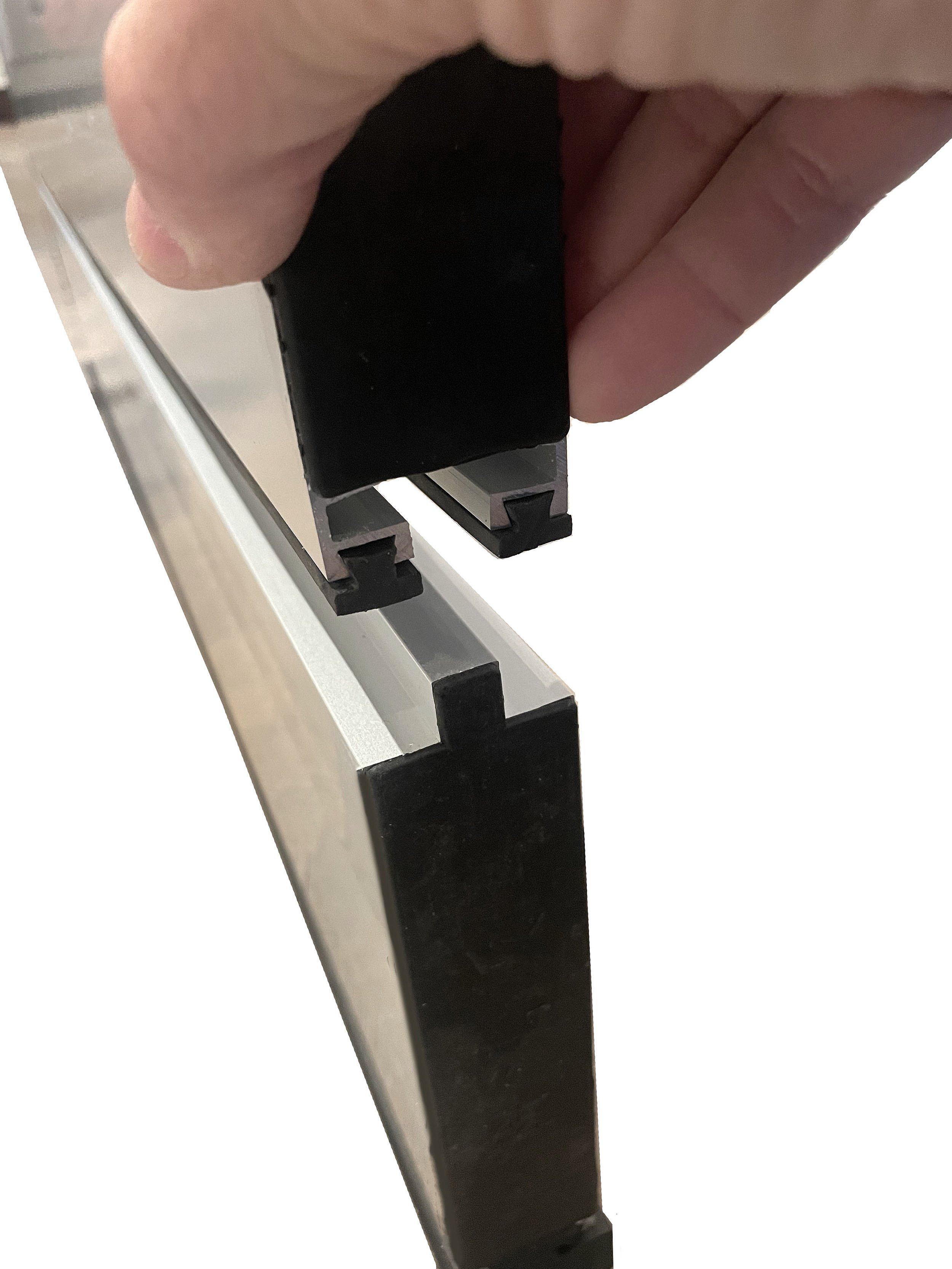

Planks have Rubber EPDM seals on the underside and posts have Rubber EPDM in the slot, which helps create a durable seal off against water infiltration.

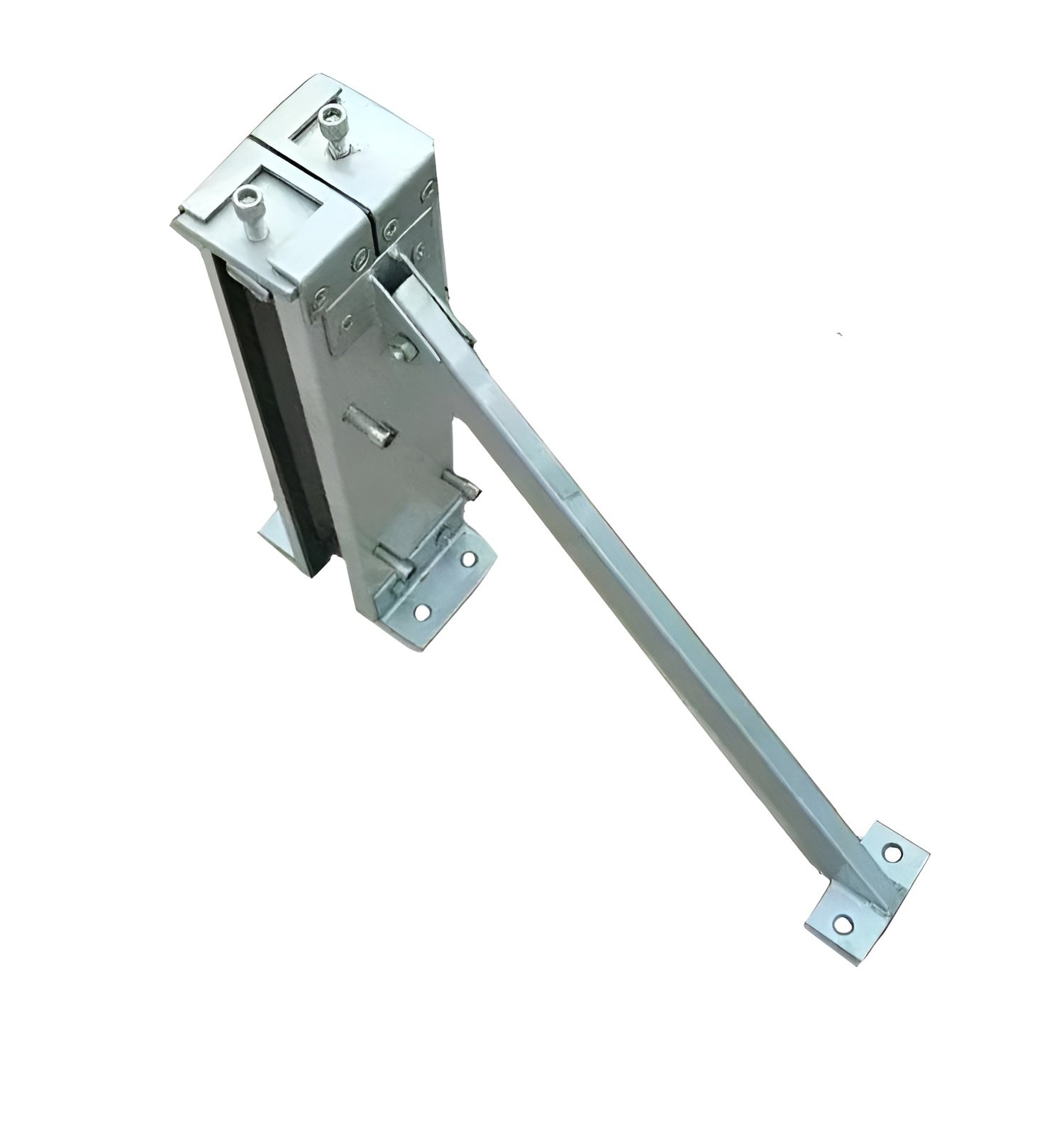

For added wind and debris resistance, flood gate planks are tightened against the seal within the posts and bracketed down from the top, so that they stay in place in even the most extreme situations.

*It is important to confirm that your structure can withstand the hydrostatic pressure of a flood for dry floodproofing standards. Consult with local PE (Professional Engineer).

Flood Barrier Mounting Options:

Choose between inside or outside mounted posts, depending on your specific installation environment, such as your threshold construction, window or door configuration, wall construction, or aesthetic preference.

Specifications:

Posts

Post Material: 6063 T-6 Aluminum

Post Height: Varies depending on number of planks

Post Depth: 3.94” (10cm)

Post Width: 2.36”

Post Weight: 3.025lbs per ft.

Middle Post Width (Double Channel): 5.12”

Middle Post Depth: 3.94” (10cm)

Middle Post Weight: 6.05lbs per ft.

Sealing Material: Rubber EPDM

Bolts: M12 8.8mm bolt

Planks

Plank Material: 6063 T-6 Aluminum

Plank Width: Varies Depending on Opening Size

Plank Weight: 2.016lbs per ft.

Individual Plank Height: 7.37” (18.7cm)

Plank Depth: 1.58” (40mm)

Plank Extrusion Wall Thickness: 0.0787” (2mm)

Sealing Strip Material: Rubber EPDM

Tallest Protection Height: 6.14ft (10 planks)

Protection Heights:

Simple Set Up

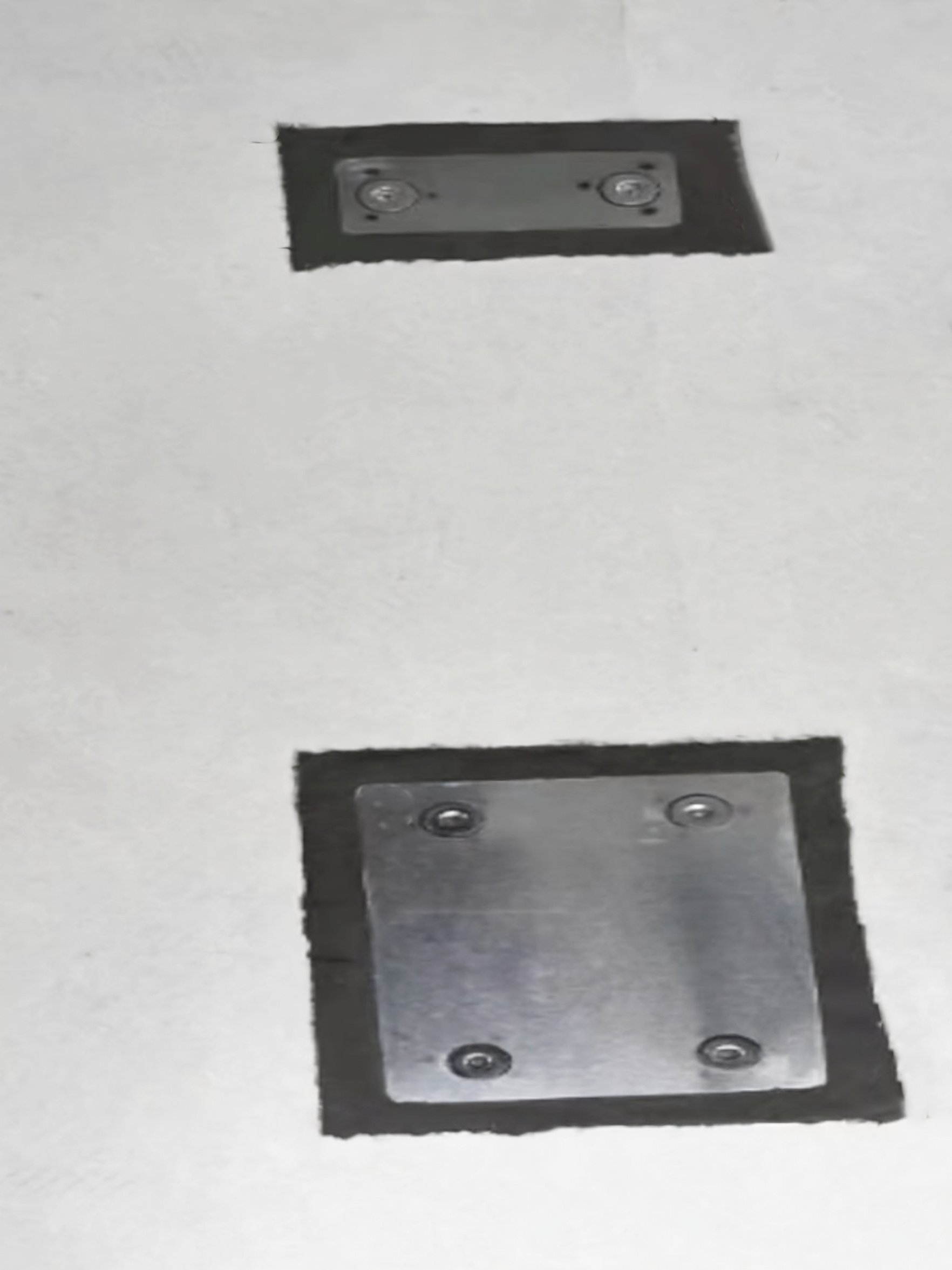

Affix Mounting Posts to Sides of Opening

Decide if you prefer to install posts inside your opening or just to the outside of the opening. We tend to prefer outside, if possible, as the wall itself offers some additional support.

Check that outside rubber seals are facing the wall in the direction that the post is to be installed and that the U-channel opening is facing the opening (ready to receive a plank).

Use a hammer drill to drill holes for expanding wall anchors (included).

Insert and expand anchors to mount posts to the wall. It is important that these be inserted into a solid concrete, cinderblock, or cement wall, for greater stability of the system.

Insert Planks Into U-Channel Posts

When a flood is expected, insert planks into the U channels on either side of the door opening.

It is important to loosen the tightening bolts and the top locking bracket, in order to get slats into the opening.

Be sure that rubber seal is facing downwards in order to make a good seal with the ground below. Apply some pressure to the lower slat to create a good seal.

Continue to insert slats until all flood barrier slats are in position, ready for tightening.

Note: If reflective warning tape was selected with your order, place the slat with tape last (at the top).

Tighten Planks Into U-Channel Posts

Use the included Allen wrench to tighten flood planks into position and against the internal rubber seals.

Insert top locking clamps into the post top slot. Use the Allen wrench to tighten down the clamps and to apply pressure to flood planks below, enhancing the seal between slats.

Use the tightening bolts on the posts to tighten down the planks within the U-channel and to ensure a seal with the neoprene strips within the channel.

When a flood is over, simply remove planks in the reverse order, clean off any debris, dry and store your flood barrier for future use.

For information about center posts, ground anchoring brackets, baseplates and post and plank buttresses, please review our complete instructions.

Hammerhead™ Post Options:

Outside Mount Post

Inside Mount Post

Center Post

Corner Post

Flood Barrier Accessories:

Get In Touch Today

Frequently Asked Questions

-

-

Download the complete Hammerhead™ aluminum flood gate Installation Instructions HERE

-

For initial installation and to attach support posts to either side of the opening to be protected, have a hammer drill ready to drill the necessary holes for the expanding mounting bolts.

When installing planks in advance of a flood, use our included Allen wrench to tighten down planks and to secure the upper locking plate.

-

The Hammerhead™ aluminum flood barrier is manufactured using high quality extruded 6063 T-6 Aluminum planks and posts and casted fitting. Hardware is made from stainless steel. Components are designed to be durable as well as weather and rust resistant.

-

The lower Hammerhead™ flood plank has rubber EPDM seal, which creates a strong seal with the ground below. Some consideration should be given to uneven ground surfaces as the plank is inflexible and while there is some flexibility to the EPDM seal, the ground should be patched and relatively level to achieve a good seal off.

In situations where there are pavers in sand, gravel, or dirt as a subsurface, it is important to add a concrete footer underneath the Hammerhead bottom rail to ensure a good seal.

This footer should extend across the entire width of the barrier, including the U-Channel Posts.

The footer should be positioned right up against your structure, to ensure a good connection and seal off. If the footer is being placed between two property walls, make sure that it is positioned to abut these walls to create a secure seal.

For more information, visit our Hammerhead Instruction page HERE.

-

The Hammerhead™ aluminum flood barrier can handle floods up to 6ft, with each plank measuring just under 8” in height.

Order barriers with the number of planks you need to achieve the protection height you need for your specific scenario. Standard recommended size is 5 planks or 3.07ft.

-

Allow about an hour to install the posts permanently to either side of your opening and to insert the flood logs for the first installation. Installation of planks happens in minutes, with a few extra minutes to tighten down each plank and the top clamp.

-

The Hammerhead™ flood barrier can be extended using center posts for additional support.

We recommend planks up to 10ft for lower heights (3.28ft or 5 planks) and generally suggest using center posts for lengths longer than that.

Depending on the height of the barrier being installed, we may recommend an additional support buttress against the center post, or positioned at the middle of the planks.

-

Depending on your specific scenario, you can install the posts either on the inside or the outside of the opening to be protected. We tend to prefer outside installations, as the wall behind the post offers additional support, but if your wall is durable, there is no problem installing the panels inside the opening, using our expanding anchoring bolts.

Note that the inside mounting method will narrow the opening slightly (about 4 inches on either side) and as such may not be as well suited for narrow doorways. Whichever mounting method you choose, confirm that the planks will clear any hinges, molding, or door hardware.

If you aren’t sure, email us at sales@garrisonflood.com with an image of your opening and we can offer our suggestions

-

Yes. The Hammerhead™ center post can be made removable by using drop in anchor bolts. See our instructions HERE to learn how to make your center posts removeable.

-

Yes - we offer 90 degree turn sections that allow you to make a turn. This is ideal when using Hammerhead to protect an entire perimeter.

-

Hammerhead™ posts need to be installed on a flat and durable surface, so that a good seal is created between the wall and the post. When installing posts, we suggest installing them against brick, cinderblock, or concrete walls, as the planks will experience tremendous hydrostatic pressure as flood waters rise.

-

You can hose down or pressure wash the planks after use, making sure to clear away any stuck on debris. Be careful not to disturb the damage the rubber seals if using a pressure washer.

Standard household cleaners can be used to clean stubborn dirt.

Stack sections after they are completely dry.

-

Hammerhead is proudly manufactured in the USA. All products currently ship from our regional warehouse in Coconut Creek, Florida.

-

Typically, posts are permanently attached to the opening once installed. Prior to installation of the planks, we recommend checking the bolts are secure and the post is seals well to the wall.

Installing the Hammerhead™ flood log system permanently, ensures that a good seal is created, as we recommend that you apply silicon to the sides of the installed posts to enhance the seal.

It is possible to install posts using standard drop in masonry anchors, which allow for removable center posts but we generally do not recommend this method for standard post mounting.

-

Yes, the Hammerhead™ posts are removeable, however we recommend keeping them in place for the most optimal seal for your flood protection.

-

Yes. Hammerhead™ flood barriers can be painted to match the color of your structure. We recommend removing the internal seals from the posts before painting and ensuring that the tightening bolts and the bracket inside the flood barrier posts and the remains free to move and tighten when needed for a flood.

-

We recommend inspecting the Hammerhead posts and planks on a bi-annual basis to guarantee integrity of materials and rubber seals, however there is typically no regular maintenance required.

-

Contact us and speak with a flood specialist today to determine the number and type of panels that are right for you. We recommend getting exact measurements of your opening before contacting us. Pictures of each opening are also helpful to help determine if Hammerhead™ is right for you.

Our Mission

Protect

Protect the places and things that are most important

Block

Stop flooding in its tracks with a variety of solutions

Prepare

Become a trusted resource for all things flood preparedness and protection

Made In The USA

The Hammerhead Aluminum Flood Barrier System is proudly made in the USA